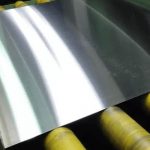

S32750 S32205 2205 2507 904L S31803 Dupleks zanglamas po'latdan yasalgan qatlam

2205 2507 904L S32750 S32205 S31803 Dupleks zanglamaydigan po'latdan yasalgan buyumlar metall shtamplash qismlari, katta mexanik uskunalar qismlari va shassi uchun ishlatiladi. Va kichik elektron aksessuarlar, turli xil apparat ehtiyot qismlari. zanglamaydigan po'latdan yasalgan plastinka kislotaga chidamliligi, gidroksidi qarshilik, tortishish kuchi va oqim kuchiga ega. Jilolash uchun ko'proq mos keladi, yuzada pufakchalar yo'q, teshiklar va boshqalar. Bundan tashqari, yuqori haroratga nisbatan sezgirlikka qarshi kuchli qarshilik mavjud.

| Sinf | 2205 2507 310S 904L S32750 S32205 S31803 Dupleks zanglamaydigan po'latdan yasalgan choyshab |

| Jarayon | Issiq haddelenmiş yoki sovuq haddelenmiş |

| Yuzaki ishlov berish | № 1 / 2B / №4 / HL / Brushed / BA / 8K Oyna / Kabartmalı / Yivli va boshqalar (himoya qilish uchun qog'oz yoki PVX plyonka bilan) |

| Standart | JIS, AISI, ASTM, GB, DIN, EN va boshqalar. |

| Qalinligi | Sovuq haddelenmiş (0,3-3 mm). Issiq haddelenmiş (3-100 mm) |

| Kengligi | 600-2000 mm yoki moslashtirilgan |

| Uzunlik | 1000-6000 mm yoki moslashtirilgan |

| Tovar belgisi | TISCO, BAO STEEL, BAOXIN, ZPSS, LISCO, JISCO va boshqalar. |

| Paket | Standart eksport dengiz to'plami (suv o'tkazmaydigan kraft qog'oz + yog'och pallet + temir chiziqli to'plam) |

| Standart o'lcham | 4 'x 8' ---------- 1220mm x 2348mm 4 'x 10' --------- 1220mm x 3048mm 5 'x 10' --------- 1524mm x 3048mm 5 'x 20' --------- 1524mm x 6096mm |

TISCO zanglamaydigan po'latdan yasalgan plitasining spetsifikatsiyasi

| Sovuq haddelenmiş zanglamas po'latdan yasalgan choyshab / plastinka qalinligi bardoshlik diapazoni | ||||

| Qalinligi | Katta bag'rikenglik | Oddiy bardoshlik | Kichik bag'rikenglik | Bag'rikenglik yo'q |

| 0,4 mm | 0.3-0.32 | 0.33-0.37 | 0.37-0.39 | -0.39 |

| 0,5MM | 0.4-0.42 | 0.43-0.47 | 0.47-0.49 | -0.49 |

| 0,6 mm | 0.5-0.52 | 0.53-0.56 | 0.57-0.59 | -0.59 |

| 0,7 mm | 0.6-0.62 | 0.63-0.67 | 0.67-0.69 | -0.69 |

| 0,8 mm | 0.7-0.72 | 0.73-0.77 | 0.74-0.79 | -0.79 |

| 0,9 mm | 0.8-0.82 | 0.83-0.87 | 0.87-0.89 | -0.89 |

| 1.0MM | 0.89-0.9 | 0.91-0.94 | 0.94-0.99 | .0,99 |

| 1,2 mm | 1.02-1.08 | 1.09-1.15 | 1.16-1.18 | -1.18 |

| 1,5 mm | 1.32-1.38 | 1.39-1.45 | 1.46-1.48 | -1.48 |

| 2.0MM | 1.72-1.79 | 1.8-1.86 | 1.87-1.9 | -1.9 |

| 2.5MM | 2.23-2.36 | 2.32-2.42 | 2.42-2.47 | .42.48 |

| 3.0MM | 2.7-2.77 | 2.78-2.85 | 2.85-2.9 | .92.9 |

Issiq haddelenmiş zanglamas po'latdan yasalgan choyshab / plastinka qalinligi bardoshlik darajasi | ||||

Qalinligi | Katta bag'rikenglik | Oddiy bardoshlik | Kichik bag'rikenglik | Bag'rikenglik yo'q |

3.0MM | 2.6-2.75 | 2.75-2.85 | 2.86-2.9 | .92.9 |

4.0MM | 3.5-3.6 | 3.6-3.75 | 3.76-3.95 | .93.95 |

5.0MM | 4.5-4.6 | 4.6-4.75 | 4.75-4.95 | .94.95 |

6.0MM | 5.4-5.6 | 5.6-5.75 | 5.75-5.85 | .85.85 |

8.0MM | 7.3-7.5 | 7.5-7.65 | 7.65-7.85 | .87.85 |

10.0MM | 9.2-9.3 | 9.3-9.6 | 9.6-9.85 | -9.85 |

12.0MM | 11.1-11.2 | 11.2-11.6 | 11.6-11.85 | .811.85 |

14.0MM | 13.1-13.2 | 13.2-13.6 | 13.6-13.85 | -13.85 |

Kimyoviy tarkibi va mexanik xususiyatlari:

| ASTM | C% | Mn% | P% | S% | Si% | Cr% | Ni% | Mo% |

201 | .10.15 | 5.5-7.5 | -0.06 | -0.03 | .001.00 | 16.0-18.0 | 3.5-5.5 | - |

202 | .10.15 | 7.5-10.0 | -0.06 | -0.03 | .001.00 | 17.0-19.0 | 4.0-6.0 | - |

301 | .10.15 | ≤2.00 | -0.045 | -0.03 | .001.00 | 16.0-18.0 | 6.0-8.0 | - |

304 | .00.08 | ≤2.00 | -0.045 | -0.03 | -0.75 | 18.0-20.0 | 8.0-10.5 | - |

304L | -0.03 | ≤2.00 | -0.045 | -0.03 | -0.75 | 18.0-20.0 | 8.0-12.0 | - |

309S | .00.08 | ≤2.00 | -0.045 | -0.03 | -0.75 | 22.0-24.0 | 12.0-15.0 | - |

310S | .00.08 | ≤2.00 | -0.045 | -0.03 | .1.50 | 24.0-26.0 | 19.0-22.0 | - |

316 | .00.08 | ≤2.00 | -0.045 | -0.03 | -0.75 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

316L | -0.03 | ≤2.00 | -0.045 | -0.03 | -0.75 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

317L | -0.03 | ≤2.00 | -0.045 | -0.03 | -0.75 | 18.0-20.0 | 11.0-15.0 | 3.0-4.0 |

321 | .00.08 | ≤2.00 | -0.045 | -0.03 | -0.75 | 17.0-19.0 | 9.0-12.0 | - |

347 | .00.08 | ≤2.00 | -0.045 | -0.03 | -0.75 | 17.0-19.0 | 9.0-13.0 | - |

405 | .00.08 | .001.00 | -0.04 | -0.03 | .001.00 | 11.5-14.5 | .0.60 | - |

409 | .00.08 | .001.00 | -0.045 | -0.03 | .001.00 | 10.5-11.75 | .0.50 | - |

430 | .120.12 | .001.00 | -0.040 | -0.03 | -0.75 | 16.0-18.0 | .0.60 | - |

434 | .120.12 | .001.00 | -0.040 | -0.03 | .001.00 | 16.0-18.0 | - | - |

444 | .00.025 | .001.00 | -0.045 | -0.03 | .001.00 | 17.5-19.5 | .001.00 | - |

403 | .10.15 | 5.5-7.5 | -0.04 | -0.03 | .0.50 | 11.5-13.0 | .0.60 | - |

410 | .10.15 | .001.00 | -0.035 | -0.03 | .001.00 | 11.5-13.5 | .0.60 | .001.00 |

420 | 0.16~0.25 | .001.00 | -0.04 | -0.03 | .001.00 | 12.0-14.0 | -0.75 | .001.00 |

440A | 0.60~0.75 | .001.00 | -0.04 | -0.03 | .001.00 | 16.0-18.0 | - | -0.75 |

SAD2507 | -0.03 | -1.2 | -0.035 | -0.02 | -0.80 | 24.0-26.0 | 6.0-8.0 | 3.0-5.0 |

SAF2205 | -0.03 | -2.0 | -0.03 | -0.02 | .001.00 | 21.0-23.0 | 4.0-6.5 | 2.5-3.5 |

904L | -0.0.3 | -2.0 | -0.035 | -0.03 | .001.00 | 18.0-20.0 | 23.0-25.0 | 3.0- |

zanglamaydigan po'latdan yasalgan choyshabni kesish, yorish, tekshirish, ikki marta tekshirish, PVX qoplamasi, qadoqlash, jo'natish.